Many utilities in the Europe Middle East & Africa region have already implemented smart metering and faced the challenges of the rollout. Project management requires specific expertise when the installation, operation and maintenance of a communication network come into the picture.

Many utilities in the Europe Middle East & Africa region have already implemented smart metering and faced the challenges of the rollout. Project management requires specific expertise when the installation, operation and maintenance of a communication network come into the picture.

Today, the first movers are already planning and preparing for a second wave of rollouts and migrating from the first generation PLC, like FSK (frequency shift keying) and PSK (phase shift keying) based PLC to modern OFDM (orthogonal frequency division multiplex) technology. Now the main question is how this can be done while keeping the internal processes ongoing and protecting the investment. This article will provide insight into a migration of this type, enabled by G3 PLC.

General concepts

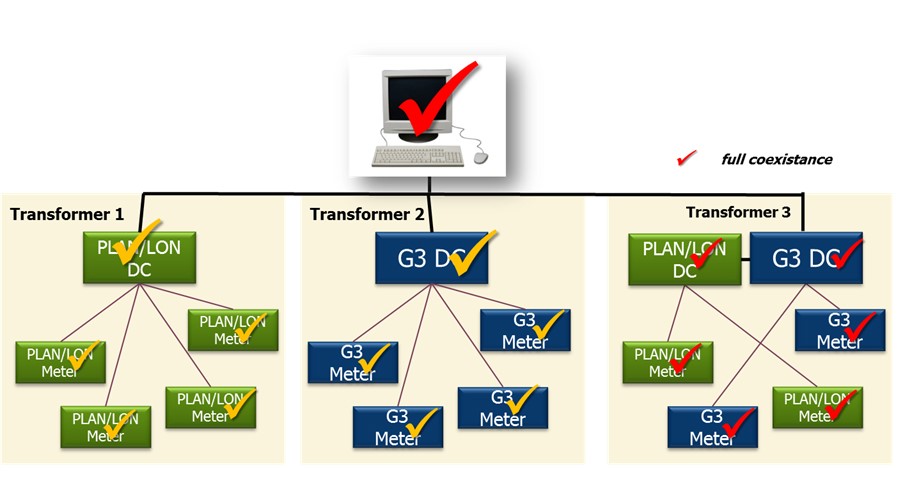

When installing smart metering for the first time, the standalone meters are typically replaced by smart ones in a mass rollout project. In this scenario all the meters connected to an LV transformer are changed within a short time period, usually within a few days. The same approach is preferred also when migrating from first generation PLC to G3. This scenario causes minimal planning effort and does not require the used technology to have any special functionality. However there are several reasons to migrate at least certain LV networks by operating the old PLC technology in parallel with the new G3-PLC technology as shown by “Transformer 3” in the diagram below.

Coexistence capability of G3-PLC

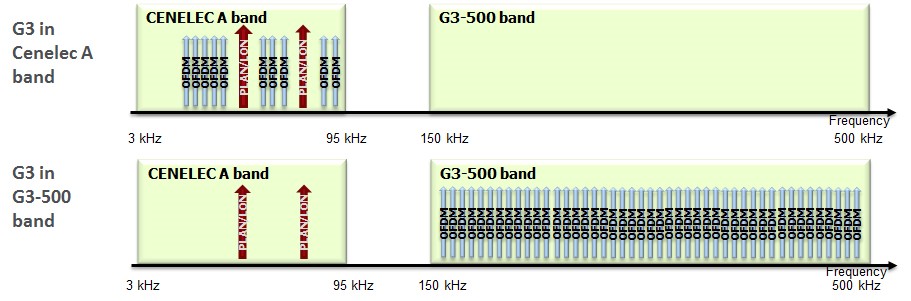

There are two alternative technical solutions to support the “Transformer 3” scenario. The two technologies can be separated either in the frequency domain (frequency multiplex) or alternatively in the time domain (time multiplex). In this article we describe the separation in the frequency domain, which is easier to implement and maintain.

The first generation PLC technologies usually use two carriers and are operated in the Cenelec bands (3-148.5kHz). The huge majority is in the Cenelec A band (3-95kHz), which is reserved for meter reading.

When G3 is operated in the 150kHz to 500kHz band (sometimes called FCC band), the frequency separation with any Cenelec band technology is given and coexistence is possible without any specific measures. However, if the OFDM based technology is operated in the Cenelec A band, an interference with the current communications will appear. In order to avoid this interference, some carriers must be notched out at the ODFM technology. The so-called tone mask feature on G3 supports frequency notching, which is not the case with all OFDM technologies. Tone mask allows the notching of any carriers and, as a result, there is no interference to the existing PLC communications and vice versa. In a case like this, FSK/PSK performance remains unchanged, however, at the cost of reduced communication speed and throughput on OFDM. However, as the G3 PLC offers significantly more bandwidth than any previous PLC technology, the reduced throughput is normally acceptable for the temporary period when both technologies are in use. Once all the devices have been replaced and the old communications network is shut down completely, the tone mask feature can be turned off remotely, and the G3 can be operated again at full speed.

The challenge in all mixed scenarios of this kind is to ensure connectivity for both technologies. This needs some additional planning, especially when meters are exchanged in a random order, for example when they reach the end of life. Proper management of this kind of migration may require the equipping of some strategic points in the network with repeaters or meters. These strategic points can be the same for both technologies since the distance that can be bridged without repetition is found to be equal for first generation PLC and OFDM-based PLC technologies in the Cenelec A band. The coexistence of G3 with PLAN and LON has been tested at Landis+Gyr’s laboratory. Several tests were carried out also with other FSK technologies, showing that coexistence can be possible even without tone masking. However, the impact of interference in terms of capacity and throughput was not tested.

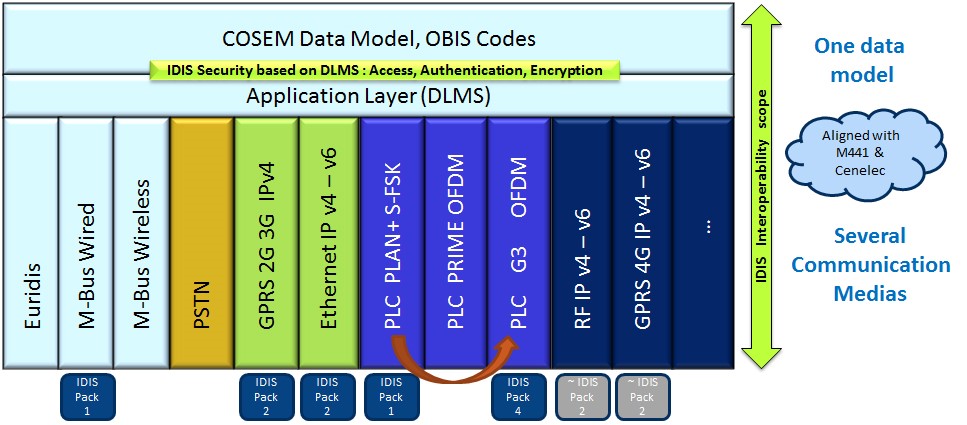

The role of DLMS/Cosem and IDIS

When considering the migration, an important aspect is the effect of the change in end-to-end use cases. If the application layer remains unchanged, the change in the communications layer will not have any impact. Standards like DLMS/COSEM are good preconditions for this. However, only real interoperability can ensure that the end-to-end use cases remain untouched and operations continue the same, independent of the communications technology used. The IDIS (Interoperable Device Interfaces Specification) standard covers this aspect and IDIS meters ensure flexible adaptation to the evolving technology.

However, migration is also possible in cases where the application layer changes. This requires system support for both application layers, or alternatively two systems must be used in parallel. This scenario requires even more specific planning as it has a big impact on the organisation and operation of the AMI infrastructure.

Summary

Smooth migration from legacy to modern PLC technology is well supported by G3-PLC. All migration scenarios from legacy LON or PLAN technologies to G3 PLC, including third-party IDIS meters, are supported in the Landis+Gyr Gridstream solution. The future proof solution protects the customer’s investment.