![]()

At the beginning of 2015, we started the first field tests on G3 PLC technology. The results described below are based on two test installations that ran for several months in our customers’ networks. Following on from these tests, we started a customer pilot, which has so far proven our findings.

Installation

The meter installation was managed differently in the two test cases. In the smaller test case, carried out on the 3-wire network in Norway, all 20 meters were installed at once. In Switzerland, 80 meters were installed on a 4-wire network in two phases: first, 15 meters placed close to the Data Concentrator, and then the rest. Initially, there was no clean-up made in either of the networks.

In both cases, the network built up automatically. The DC registered meters within 1-3 minutes after installation without any of the devices having issues.

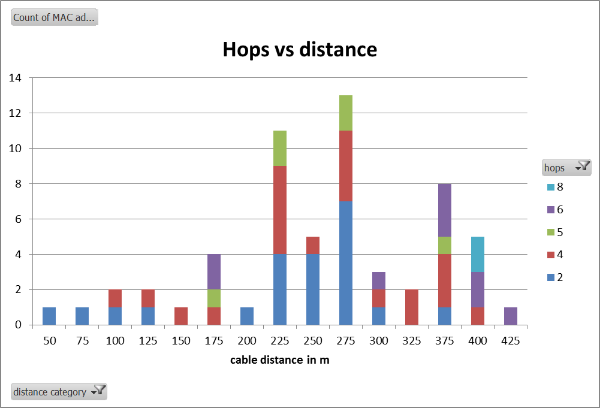

Bridged distances

As expected, the tests proved that G3 can bridge similar cable distances to PLAN PLC communications. At distances of up to 100m, all the meters use direct communication. The longest cable distance with direct communication is 325m, with a maximum of 3 hops (= hop count 8). For those who are used to credit from PLAN, you can convert the values using the equation ‘credit = (hop/2)-1’.

Communication quality

In our test implementation we measured the communication quality using the success rate of DLMS commands sent from the DC to the meters. From our experience with PLAN+ networks we know the average rate is around 75%, meaning that every 4th command needs to be resent.

In the G3 pilot networks we saw an average success rate of greater than 95%, which means that only every 20th command needed to be resent. This exceptional result exceeded our expectations. Knowing that robustness is fundamental for communication systems in harsh environments, like PLC, the G3-PLC looks truly promising.

Performance

It is difficult to compare the performances of G3 and PLAN+ in field installations. Based on our analysis, G3-PLC is 3-5 times faster than PLAN+ when installed from scratch. However, we know there are several parameters that can still be optimized

Broadcast penetration

Broadcast (multicast) enables commands to be sent to all devices – or a selected group of devices – at once. This is an important feature in cases where the demand needs to be controlled. In broadcast commands with PLAN PLC communications a 75% success rate can be achieved. In practice, the command needs to be sent at least three times to reach more than 95% of the devices. Again, G3-PLC has shown its strengths in several trials where the penetration rate exceeds 95% with a single broadcast command. Furthermore, in all cases, 100% penetration was achieved with the 2nd broadcast.

Meter firmware upgrade

One of the basic functional requirements for today’s smart meters is the capability for remote firmware upgrades. In the narrowband PLC network this has also proven to be one of the most challenging requirements to meet, as there are several communications steps in the process. In our G3 PLC field tests, we repeated the process of loading newer firmware to the installed meters several times. One of our key discoveries was that broadcasting is a heavy task on routed PLC networks and needs appropriate timing.

We decided to improve the process and, as a result, it took 17h 10m to update 5 meters with 910kB firmware in a network with 80 meters. With the newly introduced unicast mode, it took 3-4h to update one meter. We are currently developing an intelligent mode where the DC can decide when to use broadcast or unicast in the process based on the current conditions.

Network monitoring and maintenance

All communication networks need to be monitored and operated, and you need good tools to do this efficiently. The DC450 data concentrator itself offers statistics and monitoring functions that enable comprehensive analysis of the network. With G3, even more information is available to help with maintenance and troubleshooting.

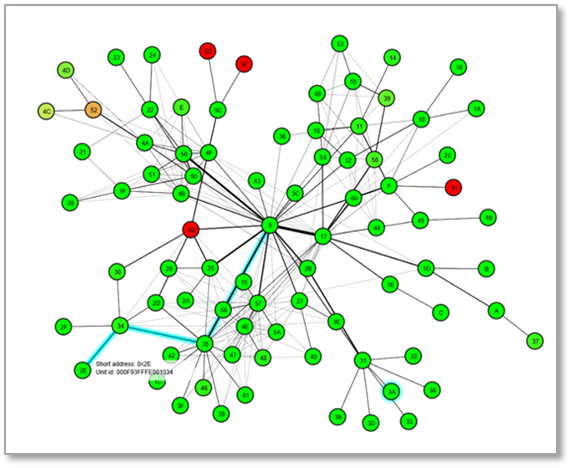

The topology shown in the picture is one of the features that G3 provides to make troubleshooting more efficient.

The image below shows:

- DC in the center

- Node colour = communication quality

- Shown on a spectrum from green to red where green is high quality and red is poor

- Line width = number of routes

- Wider lines mean more routes

- Blue line = route from a meter to the DC and back

In addition to the DC450 data concentrator, a spectrum analyzer and a protocol analyzer are needed for efficient troubleshooting in the field. The current spectrum analyzer can be used for G3 with some restrictions, but a new version will be available soon. A commercially available protocol analyzer for the field was used successfully and has also been permanently improved based on our feedback.

We can build on G3 PLC

The field tests not only proved the benefits we expected, they also showed significant potential for improvement that can be realized by adapting the parameters and the logic of the data concentrator. The very high robustness of G3-PLC under field conditions was clearly the highlight of the field tests, and exceeded our expectations. This makes G3 PLC a rock solid foundation for our Gridstream solution.

Related article